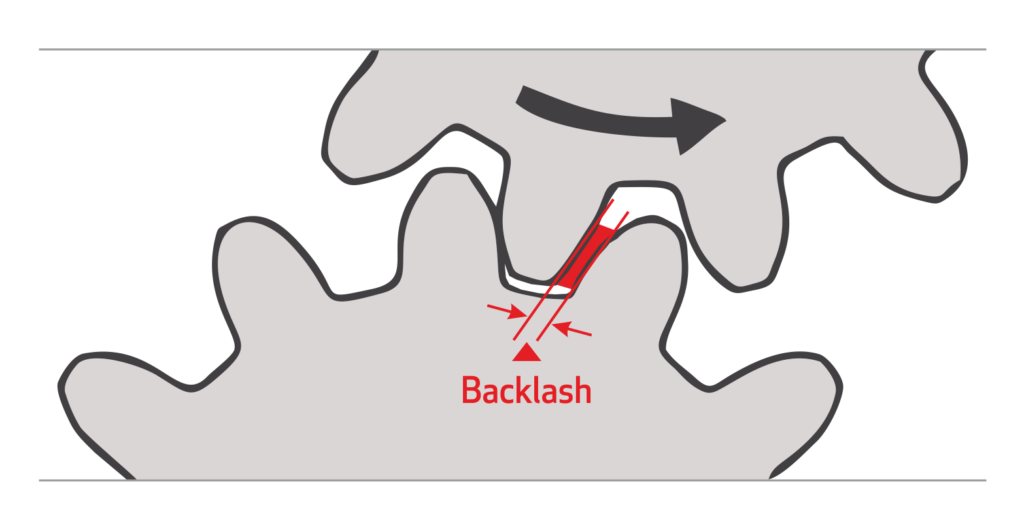

Backlash is a common issue in motor-driven systems, particularly in gear-based setups. That tiny gap between gears—known as gear backlash—can lead to big problems, such as reduced accuracy, increased noise, and unwanted vibrations. For industries that rely on precision, like automation and manufacturing, these effects are more than just a nuisance—they can disrupt entire operations.

Understanding Gear Backlash

Backlash occurs in gear systems because of the inevitable gap between gears. This mechanical play, referred to as gear backlash, causes inconsistencies in performance and increased wear over time. Transmission backlash further complicates this issue, adding variability to motor operations. The result is more maintenance, higher costs, and a decline in the efficiency and reliability of your systems. In high-precision applications, such as gimbals or indexing systems, even a slight amount of backlash can cause significant problems.

Gear Backlash Problems: Key Issues to Watch Out For

Managing gear backlash is crucial for optimal performance. Here are some common problems excessive or insufficient backlash can cause:

- Positioning Errors: In high-precision applications like CNC machines, too much gear backlash can result in motion control inaccuracies.

- Noise and Vibration: Excessive play between gears can cause unwanted noise and vibration as gear teeth collide.

- Increased Wear and Tear: When backlash is too large, gears may engage unevenly, accelerating wear and causing potential damage.

On the other hand, too little backlash can cause binding, excessive friction and overheating. Striking the right balance is essential for gear efficiency and longevity.

A Simple Solution with Big Benefits

This is where Frameless Torque Motors by Pranshu comes in. These motors are designed to eliminate the root cause of backlash by removing the need for gears entirely. Without gears, there’s no backlash to worry about, resulting in smooth, precise motion every time. This makes them a smart choice for applications where accuracy is crucial.

Why It Matters

Adopting these frameless torque motors isn’t just about eliminating backlash—it’s about improving your operations’ overall efficiency and reliability. With smoother operations, reduced vibration, and enhanced precision, Pranshu’s motors help you maintain the quality and consistency your applications demand.

Take the Next Step

If you’re tired of dealing with the harmful effects of backlash and transmission backlash in your motor systems, consider switching to Frameless Torque Motors by Pranshu. They offer a straightforward, gear-free solution that enhances precision and boosts performance. Don’t let a small gap create big problems—experience the difference today.