Motors are the biggest consumers of energy in industrial applications, puling around 74% of the energy consumed by the industry. A majority of the world has shifted from to IE3 motors to ensure more efficiency and better power-saving. India has banned IE1 motors since October 2017. As of 2020, around 68% of all motors in India are IE2 motors, and around 23% are IE3 motors. While IE2 motors have become the mainstay of Indian industry, the country is now moving towards IE3 motors to further improve its power-saving game.

What are IE classes?

Based on their energy efficiency, the IEC International Efficiency 60034-30-1 standard classifies motors into 4 International Efficiency classes: IE1 IE2, IE3, and IE4. To know more about these classifications, and how motor efficiency makes a difference in power saving, read our blog here.

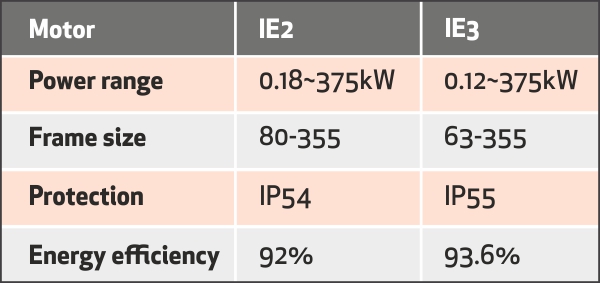

The present article illustrates the major differences between IE2 and IE3 motors.

Design and efficiency

To achieve higher efficiency, IE3 motor design differs from that of the IE2 motor. IE3 motors feature a higher amount of copper and steel, which also makes a significant difference in efficiency. IE 3 motors feature a smaller frame size than E2 motors and yet possess a wider power range and better protection standards.

An IE 2 motor has an efficiency of around 92-3% whereas an IE3 motor has an efficiency of around 93.6%. These motors could be running continuously in say a warehouse conveyor belt, operating for 3500 hours for an entire year. In that case, the more efficient IE3 motor will save around 1580 kWh of energy over the year.

Protection ratings

Ingress Protection ratings or IP ratings are standards denoting level of protection for enclosures against external solids and liquids. The first digit in the IP rating refers to the level of protection against the ingress of a solid object. The second digit refers to the level of protection against liquid ingress.

IE 2 motors are enabled with IP54 protection standard which offers complete protection from dust and protection from water splashed from all directions at a flow rate of 10 LPM (liters per minute) for 5 minutes. On the other hand, IE3 motors have IP55 protection, which ensures protection from dust as well as water sprayed from water jets at a flow rate of 12 LPM from a distance of 3 meters for 3 minutes.

Energy savings

For cost-benefit analysis let us consider IE2 and IE3 motors running continuously for 20 hours a day for 365 days a year at a load of 80%. This means the motors are running for 7300 hours every year. Thus, the annual cost-benefit analysis of the two motors is as follows:

IE2 Motors: (20*0.8) X 7300 X 8/ (0.906)= Rs 1031346 / year

IE3 Motors= (20*0.8) X 7300 X 8/ (0.921)=Rs 1014549 / year

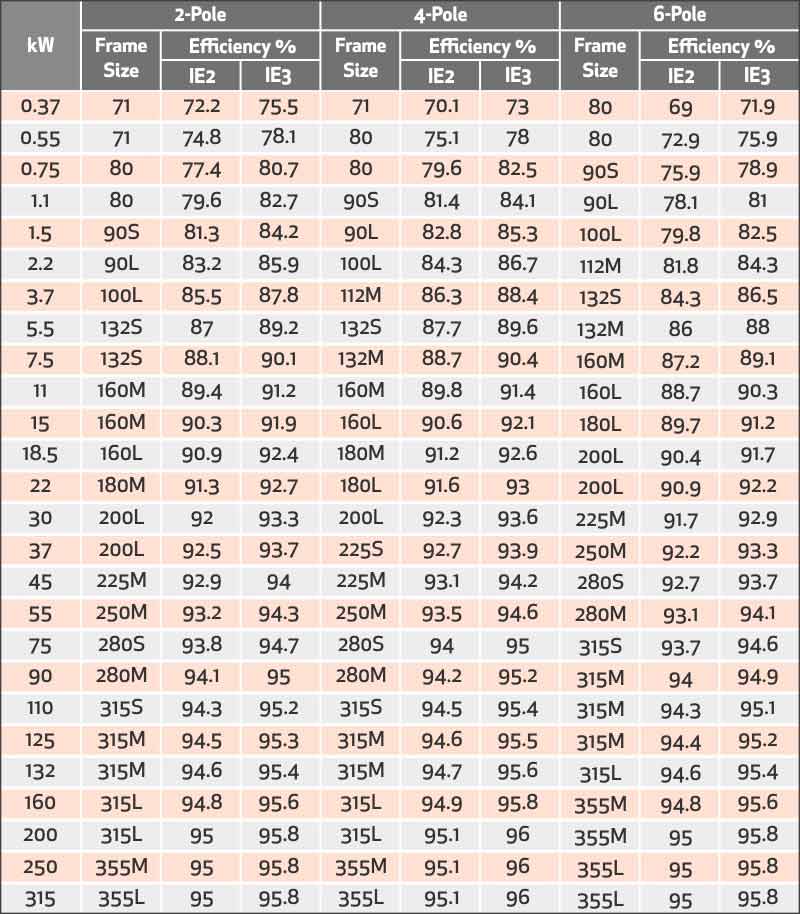

Thus, it can be seen that IE3 motors deliver considerable savings in energy bills as compared to IE2 motors. For more clarity on motor efficiency, please consider the following table.

Quality IE3 motors in India

India is presently in process of adopting IE3 motors, and the market for these motors is still emerging. Pranshu Electricals is one of few leading companies producing reliable high-quality IE3 motors in India. Backed by 20+ years of experience, Pranshu has provided motors to resolve the toughest challenges in thousands of standard and non-standard motion control applications. Pranshu is especially recognized for designing motors with near-zero failure rate, which are provided at economical price points.

For more information, visit us at https://www.pranshu.com/